Sunday, June 7, 2020

Washington County Compliant Tiny Home

Kind of, at least. This was modeled to comply both with regulations on a shed (maximum width/depth/height) as well as building codes (stair rise vs run, stud spacing).

I tried to make it as simple as possible to build, minimizing miters, thinking through build steps (e.g. insulation before or after floor boards), etc.

Reverse Engineering a Power Strip

The original goal was to make a WiFi enabled power strip and I had a thought to sell these on Tindie, so I started with a detail model of an existing power strip (APC PE76). If anyone is looking for SolidWorks models for this, I've got em.

I did throw together a simpler setup where a single outlet was Arduino controlled. This was used to cycle a crock pot to maintain a kombucha brew at the ideal temperature.

Micro-Climate Monitoring and Big Container Farming

Two more oldies from late college (and back before I used my camera frequently like a proper citizen). Both are related projects, one targeting micro climate monitoring for vineyards and the other improved plant management for outdoor marijuana farms.

The microclimate monitoring used the LoRa low power/long range wireless protocol to distribute micro-weather stations throughout the vineyard. With 3 lithium AA batteries and the modified Arduino (Moteino), we were looking at a few years of monitoring time. We would monitor temperature, humidity and leaf wetness for informing farmers of plant condition and disease prevention. This bringing significantly more resolution than the standard weather station that covered many acres.

The enclosure was essentially a Stevenson screen formed from vacuum molded baffles. This was an awesome project, but I think between building a business, managing software, hardware, and manufactured components, it was a lot to take on at once.

The second project was an idea from a marijauna farmer that we developed. There was some initial interest and we sold a few, but ultimately did not get sufficient traction. The idea was to get the planter off the ground to protect it from pests, to isolate it from the other plants to prevent wildlife from taking down the full trellising system, and to make plant management simpler and allow for rotating the plant for more equal growth.

Build photos

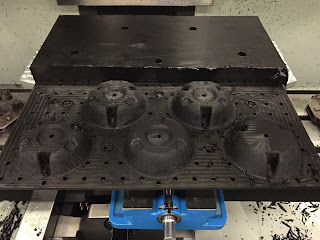

3 axis machined mold tool

Laser cut vacuum molding table

Formed and assembled parts

And a mockup for simulation and software development. Unfortunately I don't have a picture of the Python output that I wrote (or the more complete program the CS team put together), but it was a heat map interpolating between the sensors.

Weld fixture setup

Weld fixture use

Milled feet, later painted red for safety

Vibe Enhanced

This is actually two projects at different times and with different intents, but they have converged on truckifying my Pontiac Vibe.

First the padded platform, originally intended to make car camping more comfortable.

More recently, my solution to pickup trucks being overpriced. A roof rack for 4x8s and everything else. This is currently held to the car with ratchet straps at the front and back.

Build photos

Wednesday, November 28, 2018

Bicycle Clothes Dryer

Between rain and sweat, my cycling clothes were often still wet at the end of the day when I would commute back home. To resolve this, I built a little drying cabinet to put my clothes in at work.

I found the perfect cabinet on Craigslist for $10. I think it's an Ikea shoe rack, but the important part is that the drawer sides are vented. This saved a lot of drilling time.

I put the 3D printer to work for this, mostly for fun, but also for a little practicality.

I haven't used it yet after a downpour, but it's completely dried my clothes from a normal ride by noon. If nothing else, it will cut down on any odor developing in my shoes and reduce how often I need to wash my cycling clothes.

|

| Completed cabinet |

|

| Pouting dog |

I found the perfect cabinet on Craigslist for $10. I think it's an Ikea shoe rack, but the important part is that the drawer sides are vented. This saved a lot of drilling time.

I put the 3D printer to work for this, mostly for fun, but also for a little practicality.

|

| New roller. On the right in the first image. |

|

| Fan cover. Only printed one because it took too long. |

|

| Control box |

|

| Wiring |

Subscribe to:

Posts (Atom)